- Fri Dec 01, 2023 4:11 am

#66088

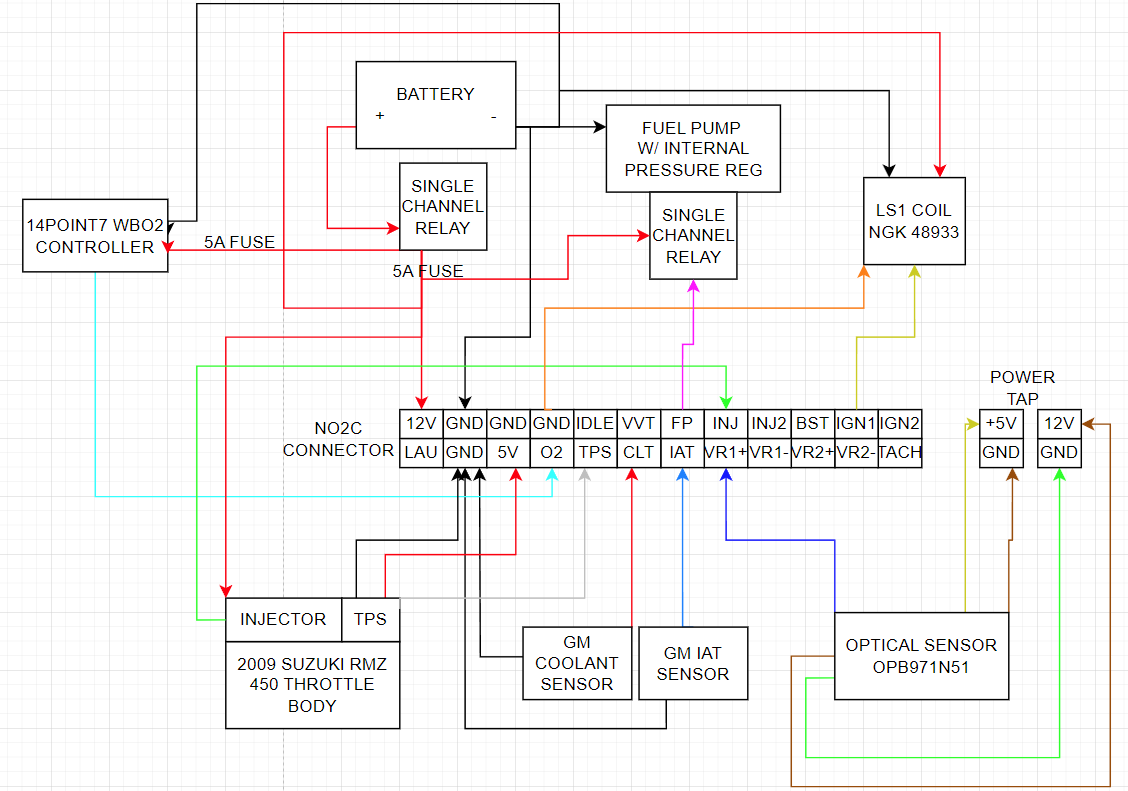

EFI RE-5 Speeduino Wiring Diagram.png (73.99 KiB) Viewed 1229 times

EFI RE-5 Speeduino Wiring Diagram.png (73.99 KiB) Viewed 1229 times

Hello again, over a year later and little progress

On the bright side, there now exists: a bike in the living room for convenient access, a colour matched wiring diagram, 3d printed 36-1 trigger wheel, brackets, an intake manifold, exhaust w/ WBO2 bung, a rough map of ignition timing and other settings, and last but not least a complete speeduino-side wiring harness that needs to be lightly spliced into the main bike harness.

Please let me know if I've made any obvious errors in the wiring. I'd tested the TPS, CLT, IAT, sensors in the harness through tuner studio and all seemed to be responding well. Optical sensor I had working on the bench, but only recently got the trigger wheel done so that will go on the bike shortly. All the individual wire groupings are twisted to hopefully prevent noise if present.

I have a 10uF ceramic cap intentionally taped to my wiring harness but I can't remember where it was meant to go... IGN signal? optical sensor signal? Also unsure of how best to handle on/off re key power vs handlebar kill switch

Plan is to get wiring done soon and start getting all the I/Os working together at once. Goal is to get it ready to tune by spring.

On the bright side, there now exists: a bike in the living room for convenient access, a colour matched wiring diagram, 3d printed 36-1 trigger wheel, brackets, an intake manifold, exhaust w/ WBO2 bung, a rough map of ignition timing and other settings, and last but not least a complete speeduino-side wiring harness that needs to be lightly spliced into the main bike harness.

Please let me know if I've made any obvious errors in the wiring. I'd tested the TPS, CLT, IAT, sensors in the harness through tuner studio and all seemed to be responding well. Optical sensor I had working on the bench, but only recently got the trigger wheel done so that will go on the bike shortly. All the individual wire groupings are twisted to hopefully prevent noise if present.

I have a 10uF ceramic cap intentionally taped to my wiring harness but I can't remember where it was meant to go... IGN signal? optical sensor signal? Also unsure of how best to handle on/off re key power vs handlebar kill switch

Plan is to get wiring done soon and start getting all the I/Os working together at once. Goal is to get it ready to tune by spring.