- Sun Nov 12, 2023 8:22 am

#65722

injector cycle idle 101kpa 10 deg.jpg (153.27 KiB) Viewed 3212 times

injector cycle idle 101kpa 10 deg.jpg (153.27 KiB) Viewed 3212 times

injector loom signal.jpg (798.52 KiB) Viewed 3212 times

injector loom signal.jpg (798.52 KiB) Viewed 3212 times

ignition dwell idle 27kpa 10deg.jpg (151.41 KiB) Viewed 3212 times

ignition dwell idle 27kpa 10deg.jpg (151.41 KiB) Viewed 3212 times

ignition loom signal.jpg (750.99 KiB) Viewed 3212 times

ignition loom signal.jpg (750.99 KiB) Viewed 3212 times

data capture.jpg (773.66 KiB) Viewed 3212 times

data capture.jpg (773.66 KiB) Viewed 3212 times

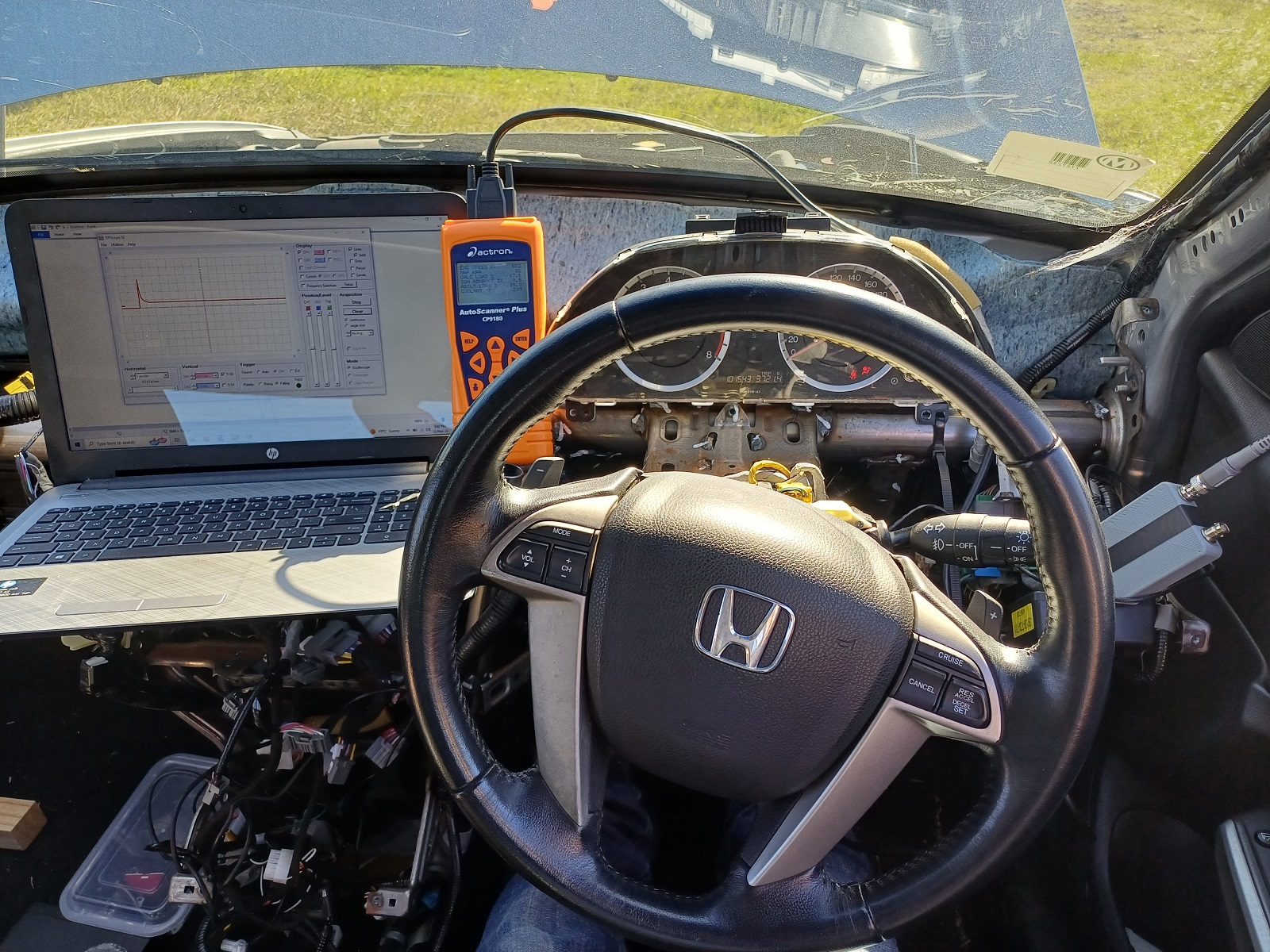

The donor car was taken for it's last drive today, as I need the axles from it for my daily driver. After a proper warmup captured a range of ballpark datapoints for setting up the speeduino on the test engine, which will use a Spartan 3 wideband O2 to refine the fueling.

Sliced into the ignition signal wire to get a contact for the oscilloscope probe. Coil on plug dwell is 2.5ms at idle, around 3ms at higher loads.

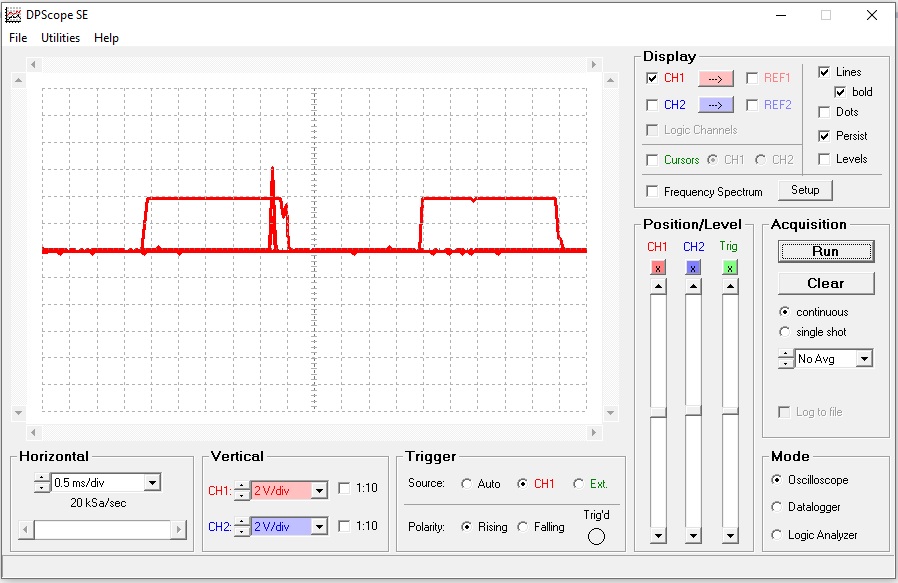

The ECU grounds the injector coil (11.6 ohms cold so expecting around 1.2A when running) so intercepted the wiring on the injector coil ground side to analyse the injector pulsewidth across a range of engine loads. Car in drive and brakes fully on, holding throttle at the desired MAP values that the speeduino will use as the engine load axis. Transmission oil got very hot but as it's off the road now not an issue.

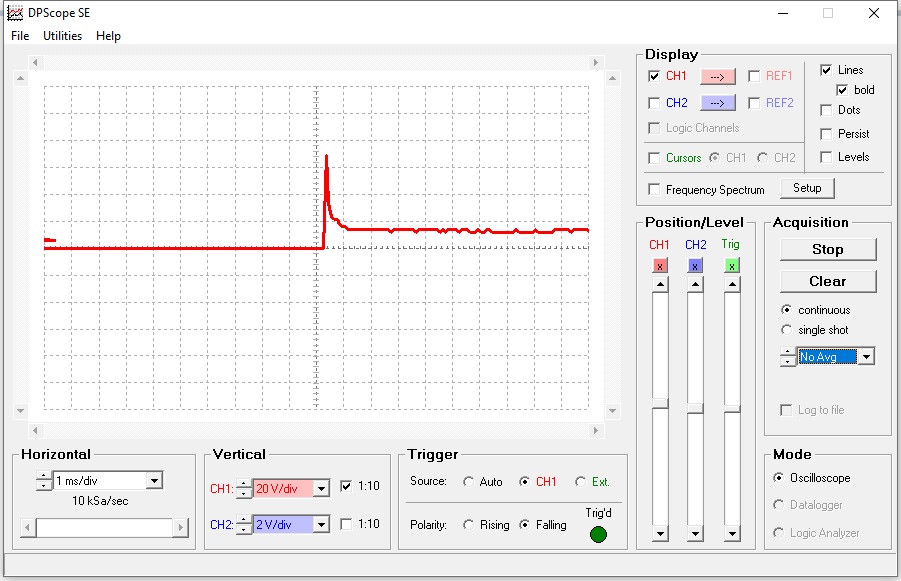

DPscope capture of full throttle injector pulsewidth - leads are set to 1:10 so that the voltage level was captured properly, however not sure they were correctly attenuated, but was really only interested in the pulsewidth anyway.

Sliced into the ignition signal wire to get a contact for the oscilloscope probe. Coil on plug dwell is 2.5ms at idle, around 3ms at higher loads.

The ECU grounds the injector coil (11.6 ohms cold so expecting around 1.2A when running) so intercepted the wiring on the injector coil ground side to analyse the injector pulsewidth across a range of engine loads. Car in drive and brakes fully on, holding throttle at the desired MAP values that the speeduino will use as the engine load axis. Transmission oil got very hot but as it's off the road now not an issue.

DPscope capture of full throttle injector pulsewidth - leads are set to 1:10 so that the voltage level was captured properly, however not sure they were correctly attenuated, but was really only interested in the pulsewidth anyway.

Attachments

Last edited by Kinetic Research on Sun Nov 12, 2023 9:02 am, edited 4 times in total.