If you are that far from your desired fixed timing of 10°BTC, then I would do a lot more than 3° change.

Sorry that was the best photo I could get. When the engine is running with the timing light it is much closer to the mark.

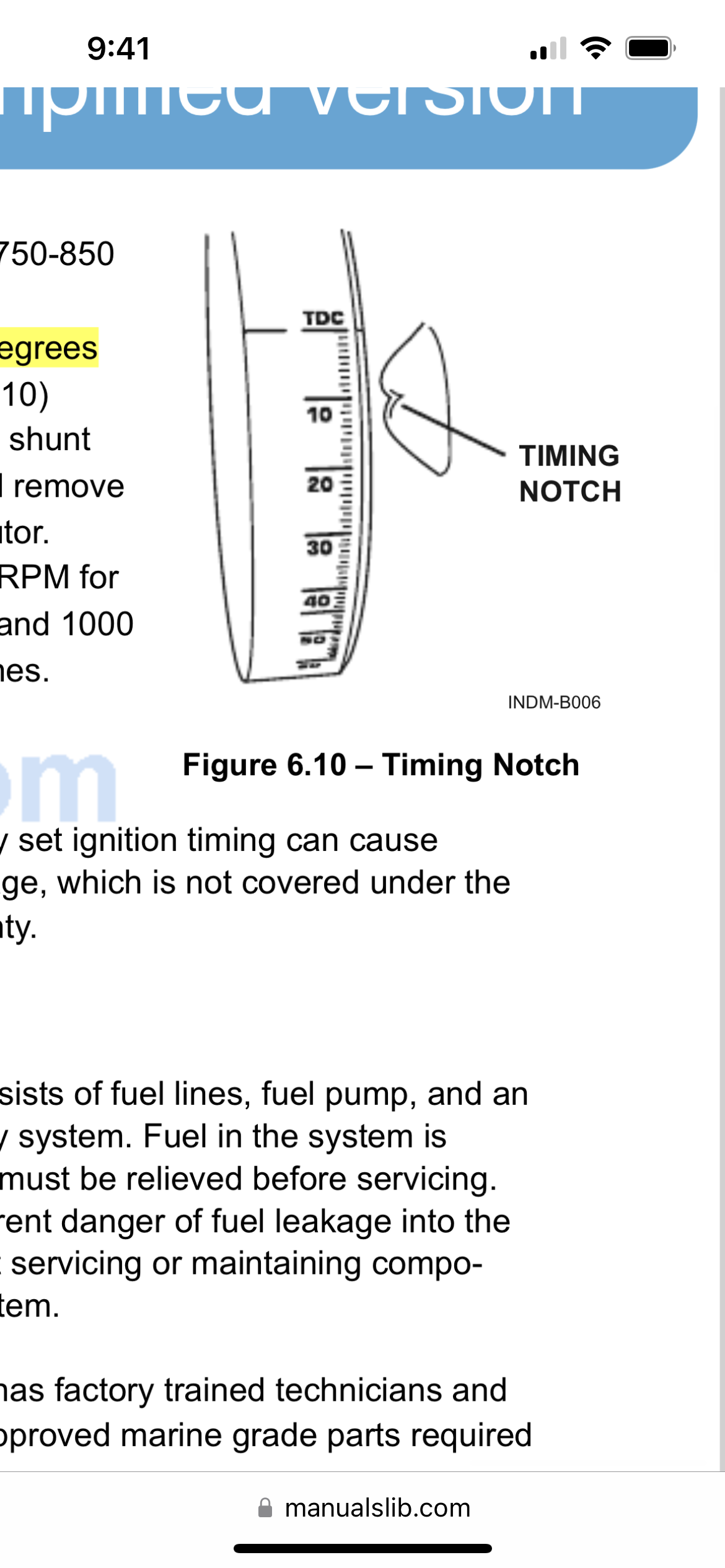

With Enable fixed/locked timing set to yes AND the value set to 10, adjust trigger angle until the marks line up just like the picture. IE, the 10* mark aligned with the notch on the block.

Screen Shot 2023-03-20 at 8.19.01 AM.png (52.2 KiB) Viewed 629 times

I set the value to 10 as above and the mark was already around 10* above the notch on the block. I would say that the timing looked pretty close to the picture you posted from the Indmar manual.

I then turned Locked timing off and proceeded with your other suggestions.

Your VE table looks like a reasonable starting point, but I would turn off ‘Multiply VE value by MAP ratio’.

This resulted in a much lower idle around 640. The idle was also not as smooth.

Make your Spark Table replicate mine. It mimics the factory timing. You can play with the timing at idle or midrange after the tune is set. Set cranking advance at 10. Turn off enable fixed timing if you haven’t already.

Slightly smoother idle oscillating between 580 and 620. I experimented with cranking advance at 10 and at 0, there didn’t seem to be any difference to starting.

On the AFR table, I would start with 12.8 everywhere for safety. 12.5 maybe OK, but may be a little rich and complicate things. AFTER you get the VE table tuned you can lean out some areas like I was able to do. This is especially helpful in the idle and midrange areas.

I made the changes without noticeable difference.

I had a bit of a play with the VE table in the range of 600 to 1200 rpm I went for values between your table and mine. Using the table below it now idles between 700 and 740. My understanding is that it should be around 800. Am I on the right track adjusting the VE table or should I also consider the spark table?

Your idle is likely high because the idle air controller isn't hooked up and working. yet another thing to do, verify what type of IAC valve indmar used. A quick Google shows a stepper type, but is could be something different, MerCruiser used both stepper and PWM types.

https://www.amazon.com/gp/product/B071S ... UTF8&psc=1

I have the throttle body above. This throttle body has 8 pins, my understanding is that 2 pins are to control the butterfly and then there 3 pins for each of the two potentiometers. I'm certain that the boat doesn't have an IAC valve.

Could it be possible that the idle is controlled by timing and fuel input alone?

Screen Shot 2023-03-20 at 9.25.35 AM.png (350.09 KiB) Viewed 627 times

5195BCD1-32F3-4E5B-AF84-BEE3E35EB0D1.png (537.08 KiB) Viewed 696 times

5195BCD1-32F3-4E5B-AF84-BEE3E35EB0D1.png (537.08 KiB) Viewed 696 times