- Wed Aug 09, 2017 7:35 pm

#20559

That aside, how the hell would aluminium construction had any influence on compression ratio?

Do you ever think through your comments before posting them or is this just a stream of consciousness exercise?

Yachtsman wrote: ↑Wed Aug 09, 2017 7:28 pmThey never got a production engine higher than 10.75:1.

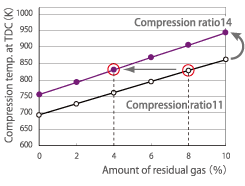

The skyacti-g is indeed 14 to 1, but is made of aluminium I'm sure if the Kettering had able to be made of aluminium it would have been able to runat 14 to 1 too

That aside, how the hell would aluminium construction had any influence on compression ratio?

Do you ever think through your comments before posting them or is this just a stream of consciousness exercise?