(continued)

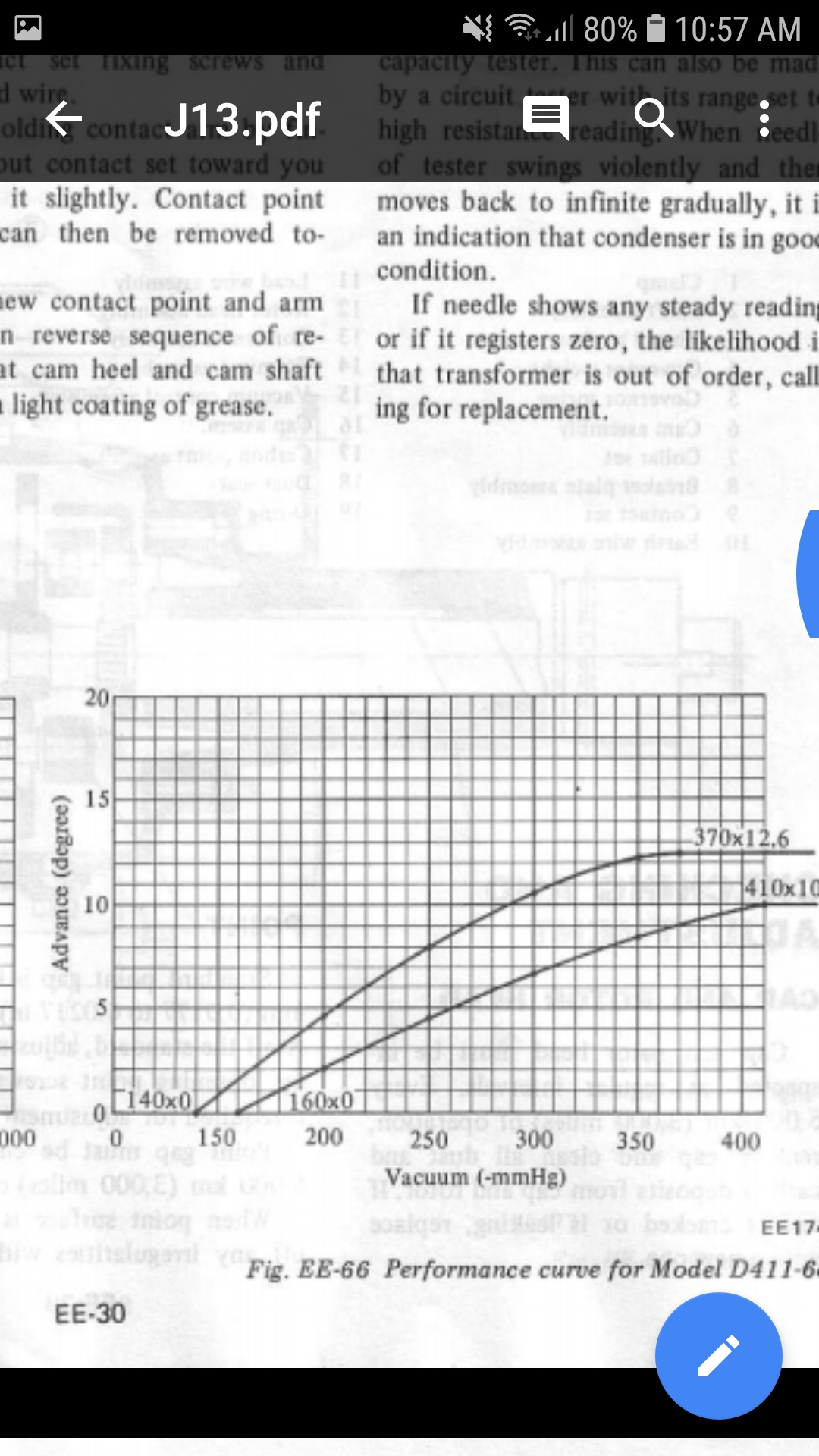

So, you have your basic "mechanical" curve plotted, and now you just need to add the vacuum-advance from Fig. EE-66 (above) to add the part-throttle engine load influence on ignition timing. Enter the significant values from the graph into the table, as +13° across 50kPa and below:

Vac_Adv_Add13_50kPa&Below.png (168.69 KiB) Viewed 10879 times

Then select the area from 50kPa to 80kPa (the active advance range) and interpolate vertically to blend the values between those two pressures:

Vac_Adv_InterpY_50-80kPa.png (158.04 KiB) Viewed 10879 times

While a number of added timing features can be added to this table that are not available or possible from a mechanical distributor; adding that vacuum-advance info onto your mechanical advance table produces this factory spec-equivalent table:

Mech+Vac Spk Tbl.png (164.09 KiB) Viewed 10879 times

Other useful information from the manual: The factory carburetor was set-up with a power valve system that activated at 80 to 85kPa, to provide power AFRs. This is no coincidence, as the vacuum-advance begins to activate at 80kPa and below for economy. So, when making your initial AFR Table you would use rich AFR for power everywhere above 80kPa, lean AFR below that for economy, and tested idle AFR in the idle area. The AFRs will be found by testing for specific numbers, but initial targets may be 12.5 to 13:1 for power, 15.5 to 16.5:1 for economy, and whatever you find in initial idle tuning for the idle-area AFR.

While some carburetors use “ported vacuum”, the Datsun J13 does not appear to, from a quick scan of the manual. Ported vacuum is a special reduced vacuum (near atmospheric pressure) only when the carburetor is at low throttle (idle range) in order to limit the advance of the vacuum canister. This “ported” effect would make the idle advance substantially less, and would have been important to factory cars using it as an emissions control (sometimes just to reduce sharp exhaust odor) since the 1950s and even earlier. While it makes the engine less responsive when used, and also run hotter, it is a part of many factory emissions schemes. For other engines, be sure to check your manual for information that may alter your timing table further, especially around idle. For other factors such as engine temperature, timing corrections are available in Speeduino.

I hope that helps with one way to reproduce information in the factory service manuals into a Speeduino Spark Table, with complimentary initial target AFR ranges. It is only a place to begin tuning, and the tables will change to be more accurate and effective for your specific engine and fuel as your tune progresses. Have fun!

David

Screenshot_20180704-105715_Drive.jpg (732.23 KiB) Viewed 10923 times

Screenshot_20180704-105715_Drive.jpg (732.23 KiB) Viewed 10923 times

Screenshot_20180704-105732_Drive.jpg (612.23 KiB) Viewed 10923 times

Screenshot_20180704-105732_Drive.jpg (612.23 KiB) Viewed 10923 times

Screenshot_20180704-105936_MSDroid.jpg (867.42 KiB) Viewed 10923 times

Screenshot_20180704-105936_MSDroid.jpg (867.42 KiB) Viewed 10923 times