- Sun Sep 27, 2020 8:38 am

#45600

IMG_20200927_102226.jpg (1.86 MiB) Viewed 5476 times

IMG_20200927_102226.jpg (1.86 MiB) Viewed 5476 times

Thanks for your help! Here is log from starting attempt where it barely run on starter motor. https://gofile.io/d/C4th4r

So these logs are now taken with 12-3 trigger wheel and older but same model hall sensor. Same setup i used earlier this summer. It seems something has changed because bike used to be driveable with this setup. I have no idea what has changed everything should be the same.

everything should be the same.

Fueling should be good and all exhaust runners are getting warm when it tries to run. It seems like when cylinders start to fire, sync loss cames in and ruins everything.

Somehow this is so sensitive for this kind of thing. Can you take a look of my logs? And get any ideas what might be good idea to try to fix this.

Here is log: https://gofile.io/d/C4th4r

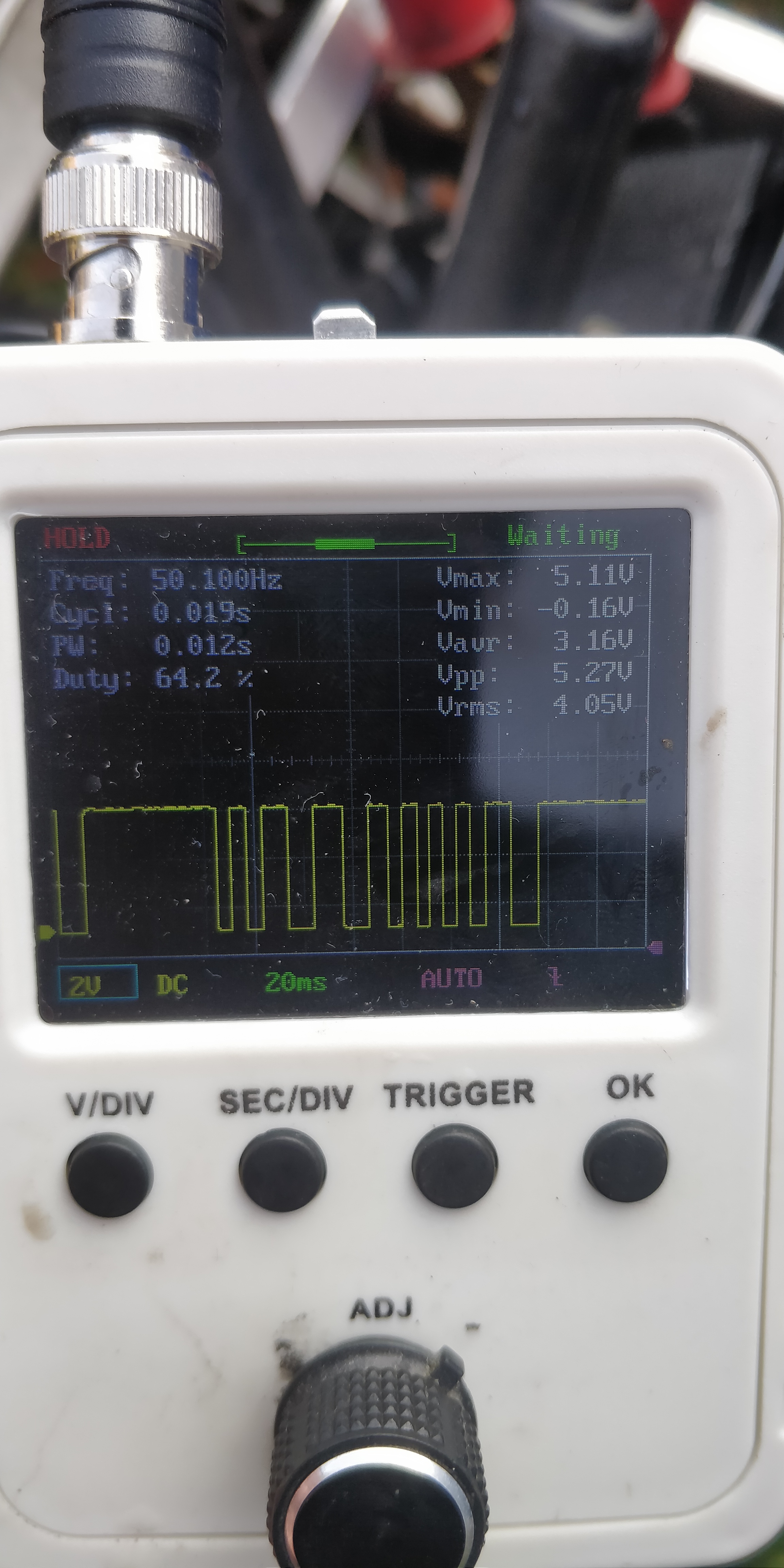

and attachments have tooth log and scope pic

So these logs are now taken with 12-3 trigger wheel and older but same model hall sensor. Same setup i used earlier this summer. It seems something has changed because bike used to be driveable with this setup. I have no idea what has changed

Fueling should be good and all exhaust runners are getting warm when it tries to run. It seems like when cylinders start to fire, sync loss cames in and ruins everything.

Somehow this is so sensitive for this kind of thing. Can you take a look of my logs? And get any ideas what might be good idea to try to fix this.

Here is log: https://gofile.io/d/C4th4r

and attachments have tooth log and scope pic

Attachments

(45.25 KiB) Downloaded 194 times