- Fri Jan 27, 2023 10:58 am

#60860

2x8_ext_driver_002.jpg (198.67 KiB) Viewed 4181 times

2x8_ext_driver_002.jpg (198.67 KiB) Viewed 4181 times

2x8_ext_driver_001.jpg (215.75 KiB) Viewed 4181 times

2x8_ext_driver_001.jpg (215.75 KiB) Viewed 4181 times

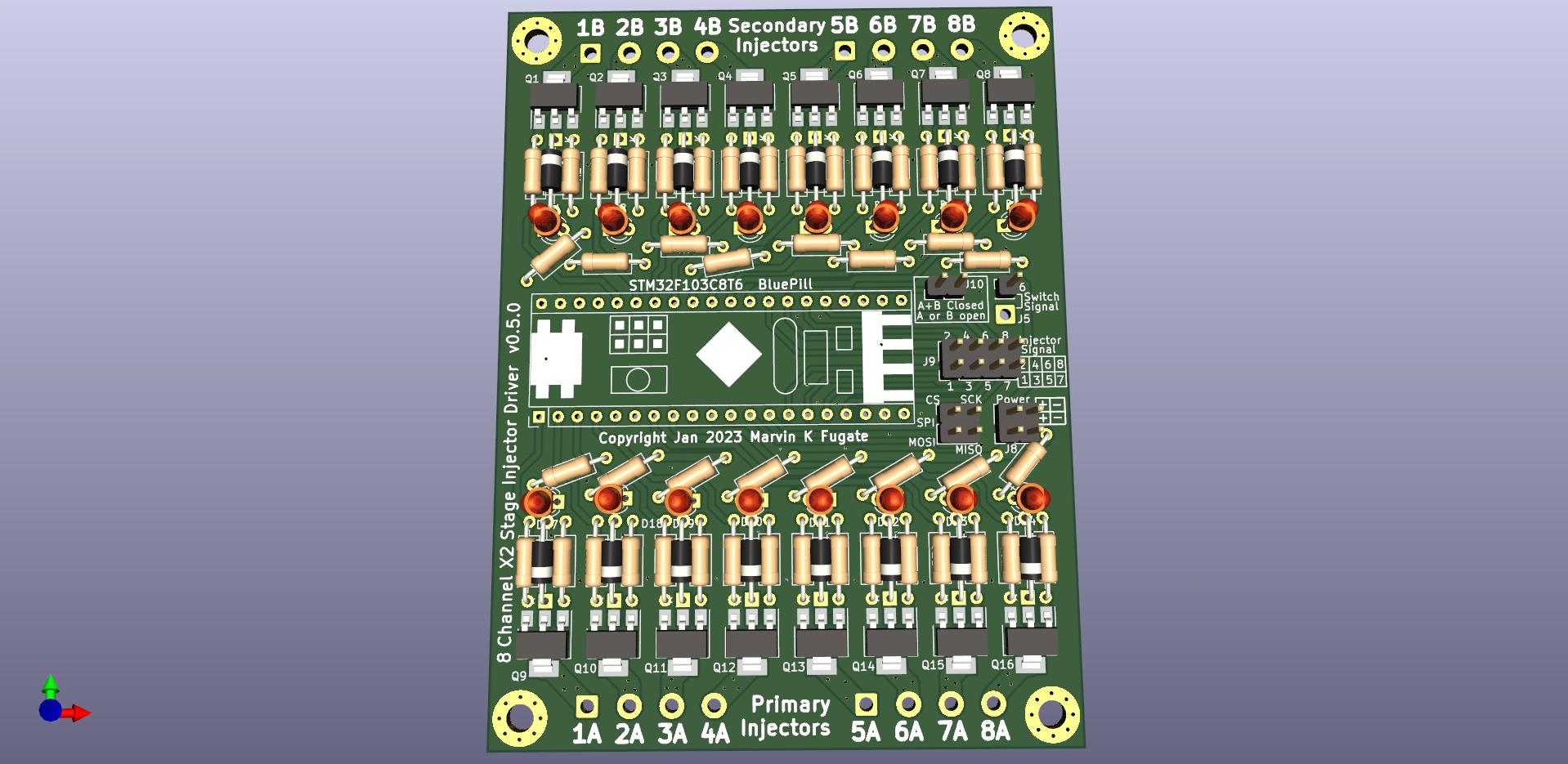

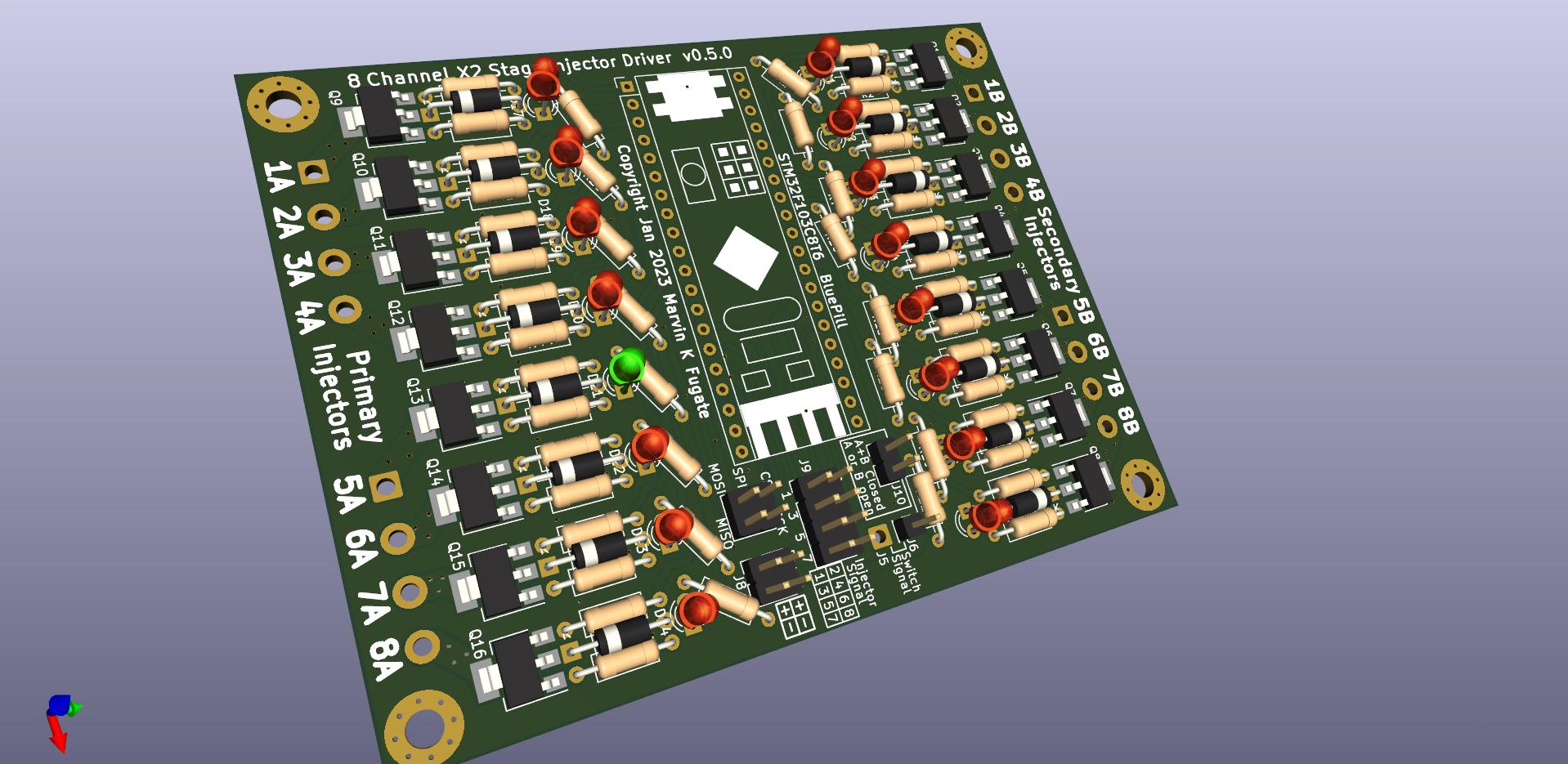

Started working on a 2 stage external injector driver board. 8 channels of input and one extra input to select stage A or B (or A+B). I started laying out the board, not quite finished, need to adjust some trace spacing and via's.

It uses a blue pill to process the inputs and outputs with a little of logic to keep any open injector(s) in the open state while switching stages to avoid lean fueling events. I might program it to optionally hold the first stage open one more complete cycle when switching for manifolds with secondary injectors mounted a lot farther upstream than the primaries(like on a tunnel ram setup).

The inputs are 8 logic level high/low signals, plus one channel to select A or B(primary or secondary stage). A jumper can be shorted to change the staging strategy from "or" to "and".

For my own use I want staged injectors to switch to really high octane race gas when I hit around 90kpa on a twin turbo LS that has 11:1 compression. This is for Drag & Drive type races so I can run on pump gas during the drive and even staging. E85 isnt really available in my home area, and Im not gonna street drive on alky or race gas all the time, so a dual fuel setup seems like a good solution.

Anyhow , probably in a month or two I might have a batch of boards made if anyone is interested I'll order some extras. its all thru-hole (except the Fets, which are easy) so if you can build a speeduino v4xx this will be easy. Its pretty small just under 3"x 4".

BTW, before I get flamed for the overkill of a Bluepill to do simple switching, I just happen to have a bunch of extras and they seem more cost effective than even simple discreet components, and I have a future possibility of SPI control or whatever.

It uses a blue pill to process the inputs and outputs with a little of logic to keep any open injector(s) in the open state while switching stages to avoid lean fueling events. I might program it to optionally hold the first stage open one more complete cycle when switching for manifolds with secondary injectors mounted a lot farther upstream than the primaries(like on a tunnel ram setup).

The inputs are 8 logic level high/low signals, plus one channel to select A or B(primary or secondary stage). A jumper can be shorted to change the staging strategy from "or" to "and".

For my own use I want staged injectors to switch to really high octane race gas when I hit around 90kpa on a twin turbo LS that has 11:1 compression. This is for Drag & Drive type races so I can run on pump gas during the drive and even staging. E85 isnt really available in my home area, and Im not gonna street drive on alky or race gas all the time, so a dual fuel setup seems like a good solution.

Anyhow , probably in a month or two I might have a batch of boards made if anyone is interested I'll order some extras. its all thru-hole (except the Fets, which are easy) so if you can build a speeduino v4xx this will be easy. Its pretty small just under 3"x 4".

BTW, before I get flamed for the overkill of a Bluepill to do simple switching, I just happen to have a bunch of extras and they seem more cost effective than even simple discreet components, and I have a future possibility of SPI control or whatever.